In the world of industrial process control, actuator valves in Dubai play a critical role in ensuring efficient and reliable operations. These valves are used to regulate the flow of various types of fluids and gases and can be controlled by a variety of actuator types. From pneumatic to electric and hydraulic, the right type of actuator valve depends on the specific requirements of the application. In this article, we’ll take a closer look at the different types of actuator valves used for industrial process control and their respective benefits.

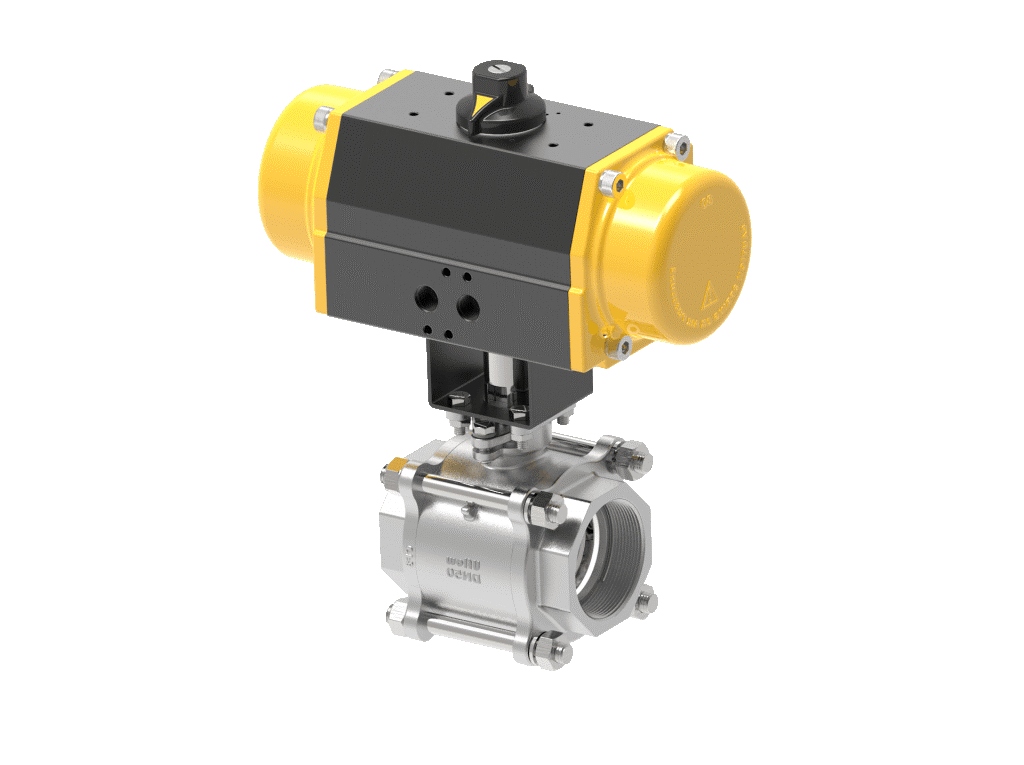

Pneumatic actuator valves are commonly used in industrial process control due to their reliable and efficient operation. These valves are controlled by compressed air, which is supplied by an external source. When the compressed air enters the valve, it creates a force that moves a piston or diaphragm within the actuator, which in turn opens or closes the valve.

An advantage of pneumatic actuator valves is their quick and reliable operation, making them ideal for applications that require frequent opening and closing of the valve. Additionally, they are relatively simple to install and maintain, resulting in cost savings over time.

However, one disadvantage of pneumatic actuator valves is that they require a compressed air source, which can be expensive to install and operate. They are also limited in their operating range, and may not be suitable for high-pressure or high-temperature applications.

Common applications for pneumatic actuator valves include controlling the flow of air or gas in HVAC systems. It regulates the flow of fluids in chemical processing and controls the movement of materials in manufacturing processes.

Electric actuator valves are controlled by an electric motor that is powered by electricity. When an electric signal is sent to the motor, it rotates a shaft that is connected to the valve, causing it to open or close. Electric actuator valves in the UAE are popular because they offer precise control over fluids or gas flow.

One of the main advantages of electric actuator valves is their accuracy. They can be programmed to open and close to specific degrees, allowing for precise regulation of fluid or gas flow. Additionally, electric actuator valves do not require any external power sources, such as compressed air or hydraulic fluid, making them easier to install and maintain.

However, there are also some disadvantages to electric actuator valves. They tend to be more expensive than other types of actuator valves. They can be slower to respond than other types of valves, which may be a drawback in applications that require rapid responses.

Electric actuator valves are used in a variety of industrial applications, including in the chemical, food and beverage, and pharmaceutical industries. They are often used in applications that require precise control over fluid or gas flow, such as in the production of medications or the mixing of chemical compounds.

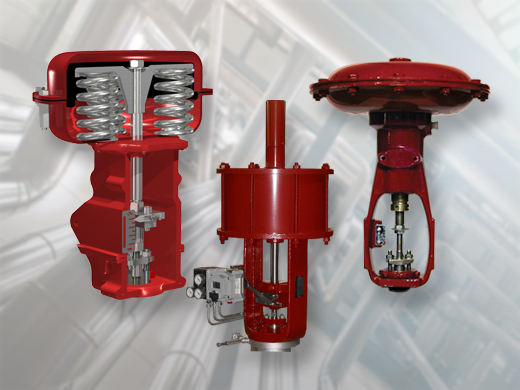

Hydraulic actuator valves are controlled by hydraulic fluid, which flows through the valve to move the actuator. When the hydraulic fluid is pressurized, it activates a piston within the actuator that moves the valve into the desired position. Hydraulic actuator valves in Dubai are commonly used in high-pressure applications where a lot of force is needed, such as large-scale manufacturing processes.

One of the main advantages of hydraulic actuator valves is their ability to operate in high-pressure environments. They are also capable of producing a high degree of force, making them ideal for use in heavy machinery and equipment. Another advantage of hydraulic actuator valves is their reliability, as they are less prone to wear and tear compared to other types of actuators.

However, there are also some disadvantages to hydraulic actuator valves. They can be more complex and expensive than other types of actuators. They also require a significant amount of maintenance to ensure proper functioning. Additionally, the use of hydraulic fluid can create environmental concerns if not handled properly.

Common applications for hydraulic actuator valves include controlling large valves in industrial process control systems, as well as in hydraulic machineries such as cranes and excavators. In the automotive industry, hydraulic actuator valves are used to control brakes and clutches in vehicles.

Apart from pneumatic, electric, and hydraulic actuator valves, other types of actuator valves are less commonly used in industrial process control. One of them is the manual valve, which is operated by a handle or lever. Manual valves are simple, reliable, and inexpensive, making them suitable for applications where precision control is not necessary. However, they require manual operation, which can be time-consuming and impractical for large-scale operations.

Another type of actuator valve is the solenoid valve, which uses an electromagnetic coil to control the flow of fluid or gas. Solenoid valves are fast-acting, energy-efficient, and can be controlled remotely. They are commonly used in applications where rapid response and precise control are required, such as in automated production lines. However, solenoid valves are more expensive than manual valves and may be susceptible to electrical interference.

The specific advantages and disadvantages of manual and solenoid valves depend on the application and requirements of the industrial process. While less common than pneumatic, electric, and hydraulic actuator valves in the UAE, these types of valves can be a viable option in certain scenarios. It’s important to consult with industry experts to determine which type of actuator valve is best suited for a particular application.

When selecting an actuator valve, you should consider several factors, including

Consulting with experts in the field can help you select the right type of actuator valve for your application.

Actuator valves play a crucial role in industrial process control. The different types of actuator valves have their respective features and benefits, and it’s important to choose the right one for your application to ensure optimal performance and efficiency. Pneumatic, electric, and hydraulic actuator valves are the most commonly used types of actuator valves, each with its unique features and applications. If you are looking for the best actuator valve in the market, have a look at the collection offered by Mohsin Trading. We have a wide range of solutions and we can help you find the best fit. Browse our collection or get in touch with our team at info@mohsintradingllc.com.