When it comes to understanding the functioning of pneumatic Actuator valves, it’s essential to delve into their working principle. Pneumatic actuators play a crucial role in various industrial applications, providing controlled movement and automation. These devices use the power of compressed air to generate motion, making them highly versatile and efficient. So, let’s dive into the intricacies of the pneumatic actuator working principle and discover how these devices facilitate precise and reliable motion control.

Pneumatic Actuator valves are essential components in various industrial and mechanical systems, playing a crucial role in converting compressed air into mechanical motion. These devices are widely used for controlling valves, gates, dampers, and other mechanisms that require precise and efficient movement.

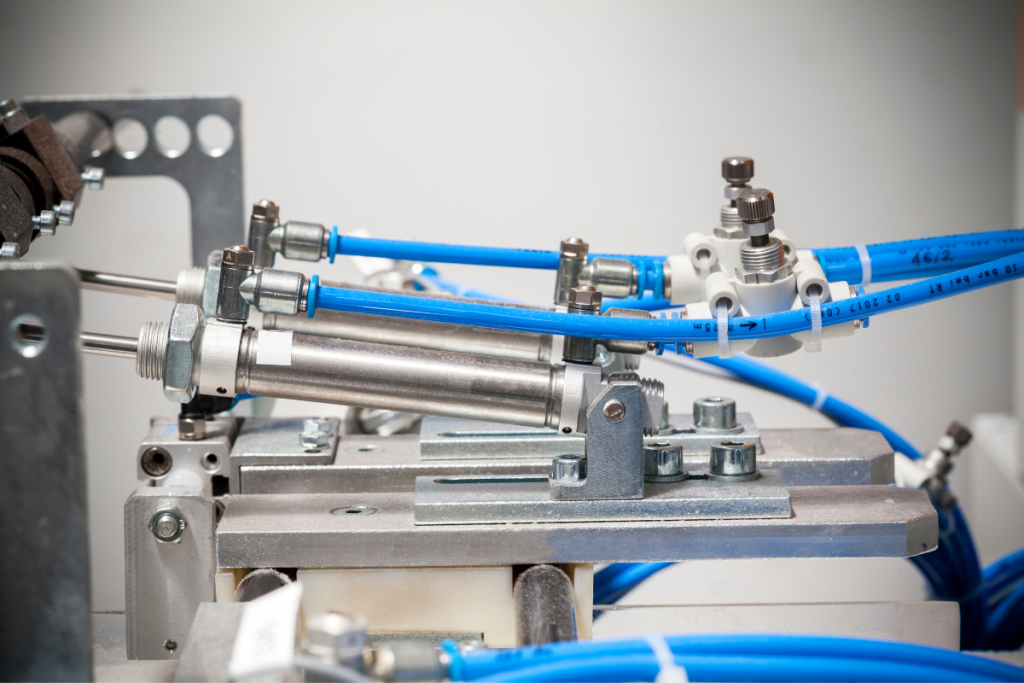

Pneumatic actuators operate on the basic principle of converting compressed air energy into mechanical motion. This working principle allows them to perform various tasks in different industries and applications. Here is a breakdown of the working principle:

Pneumatic actuators operate based on the energy conversion process from compressed air to mechanical motion. When compressed air is supplied to the actuator, it enters the actuator’s chamber, creating pressure. This compressed air energy is then converted into linear or rotary motion, depending on the Actuator valves in Dubai.

For linear actuators, the compressed air pushes against a piston, which moves the piston rod in a linear direction. This movement is either in a single direction (single-acting actuator) or in both directions (double-acting actuator). The piston’s movement is controlled by the pressure and volume of the compressed air.

In rotary actuators, the compressed air is directed into a vane or diaphragm mechanism, which converts the air pressure into rotational motion. As the air pressure changes, the vane or diaphragm rotates, providing the desired rotational movement.

To activate a pneumatic actuator, the control system sends a signal to open the air supply valve, allowing compressed air to enter the actuator. This air pressure creates a force that moves the actuator according to the desired motion, whether linear or rotary.

Deactivating the pneumatic actuator involves closing the air supply valve, and cutting off the flow of compressed air. With no air pressure, the actuator returns to its resting position or holds its current position, depending on the actuator type and design.

Pneumatic actuators are controlled using various mechanisms to achieve precise movement and positioning. These mechanisms include control valves, regulators, and sensors.

Control valves regulate the flow of compressed air into the actuator, allowing for precise control of the actuator’s speed and force. By adjusting the valve opening, the airflow is modulated to achieve the desired motion characteristics.

Regulators maintain a constant pressure of the compressed air supplied to the actuator, ensuring consistent performance and preventing excessive force or speed variations.

Sensors, such as position sensors or pressure sensors, provide feedback to the control system, enabling it to monitor and adjust the actuator’s position, force, or pressure as needed. This feedback loop ensures accurate and reliable operation of the pneumatic actuator.

Proper maintenance of pneumatic actuators is essential to ensure their optimal performance and longevity. Through these tips you can keep your pneumatic actuators in excellent condition and prevent potential issues:

versatility, reliability, and cost-effectiveness. Let’s explore some of the common industries where pneumatic actuators are widely used and specific examples of their applications along with their benefits.

Regular Inspection: Conduct routine inspections to identify any signs of wear, damage, or leakage in the actuators. Pay attention to seals, connections, and moving parts.

Lubrication: Apply suitable lubricants to the actuator components as recommended by the manufacturer. This helps reduce friction, extend the lifespan, and enhance overall performance.

Cleaning: Keep the actuators clean by removing any debris, dust, or contaminants. Use compressed air or a soft brush to clean the exterior surfaces and ensure proper functioning.

Filter Maintenance: Check and clean the filters regularly to prevent blockages and maintain consistent airflow to the Actuator valves.

Seal Replacement: If you notice signs of deterioration or leakage, replace the seals promptly. Damaged seals will compromise the actuator’s performance and lead to air loss.

The pneumatic actuator’s ability to generate linear or rotary motion makes it suitable for a wide range of tasks, including valve control, robotics, material handling, and more. It offers advantages such as quick response, reliability, and simplicity in design. To ensure the highest quality and performance of pneumatic actuators, it’s essential to source them from reputable suppliers. Mohsin Trading is a leading provider of actuator valves in Dubai, offering a comprehensive range of high-quality products that meet industry standards. You can visit our website to browse our solutions or get in touch with our team at info@mohsintradingllc.com.